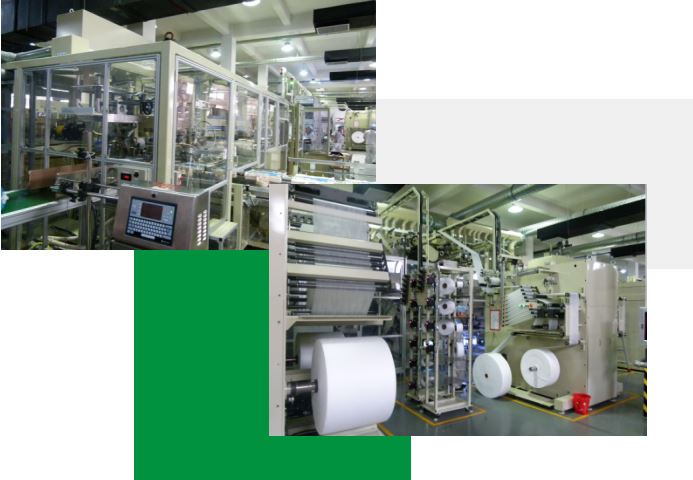

Company in line with the principle of the operation of the quality as the root, brand, and to strengthen the construction of infrastructure and equipment investment year by year, at present, the company has automatic generation equipment more than 40, including 14 baby production lines.With the world's advanced automation equipment - ZUIKO, efficient and intelligent mechanized automated production, stable product quality, effective reduction of manual and direct contact with products, and bacteria say goodbye!

Advantages of production line

Performance: average speed of 580 pieces/min, stable performance and stable product quality.

Unique skills: infrared detection, spot detection, visual detection, positioning detection, metal detection, etc.

· when entering the production workshop, the staff must wear white coats with detoxification, hats and shoe covers.The first thing you see is the finished packing of the diaper.

· this is the core material for the production of diapers. Wood pulp is mixed with high molecular weight, which is equivalent to the heart of diapers.

· the white part of the roll under the machine is rubber band, which is integrated into elastic waistline. The machine in the upper window evenly cuts a long cotton core, and the diaper is initially formed